Ece Printed Concrete

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Ece Printed Concrete

Stamped Concrete is one of the decorative concrete types that attracts attention with both its aesthetic and functional features today. In this article, while answering the question of What is Stamped Concrete?, we will examine various Stamped Concrete Applications and the factors affecting the prices of these applications. We will also provide information about Stamped Concrete Surface Coating techniques, patterned concrete applications and Stamped Concrete Casting Techniques. By guiding our readers on Stamped Concrete application methods and Stamped Concrete pattern types, we will introduce Ece Surface Stamped Concrete Company and its services. In this comprehensive article, we aim to explore the reasons for the worldwide popularity of decorative concrete while providing important tips on both functionality and aesthetics.

What is Stamped Concrete?

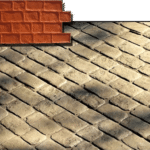

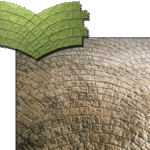

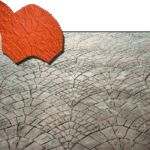

Stamped concrete is a modern surface coating technique that combines aesthetics and durability. It creates a visual appeal in architectural projects by enriching the appearance of traditional concrete with colors and patterns. This application is especially encountered in outdoor areas, but it is also frequently preferred in indoor areas. The most distinctive feature of stamped concrete is its ability to miraculously imitate different surface materials, such as stone, wood or brick.

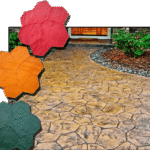

These patterned concrete applications are usually carried out using special molds. First, after the concrete is poured, the determined patterns and motifs are printed on the surface with molds. This process not only provides an aesthetic appearance; it also adds strength and durability to the surface. Thus, structures resistant to external factors are obtained.

The techniques included in the stamped concrete application methods include the stages of preparing the surface, pouring the concrete and printing the pattern. A suitable foundation must be prepared before the surface coating process. At this stage, the surface is ensured to be flat and smooth. Then, after the concrete mixture is poured, the molds are placed and the pattern creation process is started.

In addition, thanks to stamped concrete casting techniques, different pattern varieties can be obtained. This variety spreads over a wide range according to the imagination of architects and designers. For example, patterns with a natural stone appearance or modern geometric shapes are among the options that can be used in different projects. At the same time, stamped concrete prices vary according to the complexity of the application, the materials used and the workmanship.

In summary, stamped concrete has gained an important place in the world of architecture as an innovative surface coating technique. Thanks to its stylish appearance and durability, it is preferred in both interior and exterior spaces, and it creates a wide aesthetic area by offering various application methods and pattern varieties.

How is Stamped Concrete Made?

Stamped concrete is a frequently preferred floor covering method thanks to its aesthetic appearance and durability. However, there are certain steps to be followed to achieve this special design. The stamped concrete production process generally consists of the following stages:

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.1. Ground Preparation: The first step is to prepare the surface on which the application will be made correctly. At this stage, care is taken to ensure that the surface is flat and solid. Old coatings, if any, are removed and the floor is cleaned. In addition, a detailed plan is prepared on the floor by taking the necessary safety precautions.

2. Mold Installation: The prepared floor is surrounded by molds for the stamped concrete application. Molds are usually made of PVC or metal. These molds are used to create the desired shape and pattern. The correct placement of the molds and their solid fixation are important factors affecting the quality of the result.

3. Concrete Preparation: The stamped concrete mixture is prepared by enriching standard concrete with special additives. While pigments help to obtain the desired color, reforming agents are used to increase the durability of the concrete. At this stage, the proportions of water and other materials must be carefully adjusted to obtain a mixture of the appropriate consistency.

4. Application: The concrete mixture is poured into the prepared molds. After the casting process, the surface is flattened and compacted to obtain a smooth surface. This stage has a decisive effect on the durability of the concrete. The surface of the concrete is processed with the stamping control to create the desired pattern. This process is usually carried out with concrete that shows disease after a certain period of time.

5. Drying and Hardening: After the stamped concrete is applied, it is important for some moisture to remain on the surface of the concrete. This positively affects the hardening process of the concrete. Drying time varies depending on environmental conditions. Full hardening is usually achieved within a period of 7 to 28 days.

6. Supplementary Processes: Finally, the necessary maintenance and protection processes are carried out to protect the surface where the application is completed. At this stage, the application of a water-based transparent protection product will increase the resistance of the surface against external factors.

When applied carefully, stamped concrete application offers long-lasting and aesthetic results. The steps mentioned above are critical for a successful stamped concrete application and it is recommended that they be carried out by a professional team.

Stamped Concrete Applications

Stamped concrete is a material preferred in different areas with its aesthetic appearance and durability. These applications play an important role in the beautification of various projects in interior and exterior spaces. It is frequently used especially in architectural projects, park and garden arrangements, and also in commercial areas. Here are some areas where stamped concrete applications are widely used:

Walking Paths and Courtyards: Stamped concrete applications can be preferred with different pattern and color options to create walkways in gardens or park areas. In this way, the spaces become both functional and gain visual aesthetics.

Parking Areas: In parking areas in commercial or residential buildings, stamped concrete applications are quite popular in terms of durability and aesthetics. With different pattern varieties, these areas can be arranged both safely and stylishly.

Pool Surroundings: Areas around the pool can be covered with patterned concrete applications that stand out with their non-slip surface feature. This both increases safety and provides an aesthetic appearance for the pool.

Outdoor Wall Coverings: Stamped concrete surface coating methods that can be used in covering external walls give the walls a modern look. In addition, thanks to its durability, it also provides protection against external factors.

Garden Decoration: Stamped concrete applications can also be used to create decorative elements in gardens. In particular, details such as ornamental pools, flower beds and outdoor swings can be designed stylishly with this technique.

Application methods vary according to the space to be used. Stamped concrete casting techniques should be performed by professional practitioners and the quality of the materials used should increase the aesthetic appearance. The result obtained should be satisfactory in terms of both aesthetics and functionality.

Stamped Concrete applications contribute to the enrichment of spaces in terms of aesthetics and functionality. It offers flexibility to meet all kinds of needs with its variety of patterns and color alternatives. Therefore, it is an important option to consider in the design of a space.

Advantages of Stamped Concrete

Stamped concrete is a coating material that has become quite popular in the construction sector in recent years. It is frequently preferred both in interior and exterior spaces thanks to its aesthetic appearance, durability and versatility. Here are some of the advantages offered by stamped concrete:

1. Aesthetic Variety: Stamped concrete comes with many different patterns and color options. In this way, users can produce creative solutions to give their spaces a unique look. Various designs such as natural stone and wood appearances are compatible with both classical and modern architecture.

2. Durability: Stamped concrete offers a high level of durability. It is generally resistant to rapid wear, cracking or deformation. It is also quite resistant to weather conditions. Thanks to these features, it provides a long-lasting coating material.

3. Easy Maintenance: Compared to other surface coating materials, stamped concrete maintenance is extremely easy. Regular cleaning is a process that can be done with simple water and soap. Dirt and stains can be easily removed from this surface; this saves both time and money.

4. Economy: Stamped concrete, which provides various advantages in the long term, is also advantageous compared to other surface coating alternatives in terms of cost. Its low application and maintenance costs are the reason for preference for many people and businesses.

5. Fast Application: The stamped concrete application process is faster than many other coating options. The short time it takes to complete the application allows construction projects to progress quickly.

6. Environmental Awareness: Most stamped concrete solutions contain recyclable materials and stand out as environmentally friendly alternatives. This offers a significant advantage in the goal of creating sustainable structures.

Stamped Concrete has many advantages, both aesthetic and functional. This material, which has minimal disadvantages, has become an indispensable part of modern structures. Users can make their spaces both stylish and durable by taking advantage of these advantages.

Stamped Concrete Prices and Affecting Factors

Stamped concrete prices vary according to the size of your project, the materials used, and the types of patterns selected. Therefore, it is very important to first analyze which stamped concrete application methods will be used to determine the cost of a job. In general, there are several main factors to consider in pricing.

Material Quality

The quality of the materials used for stamped concrete surface coating processes plays an important role in determining prices. Quality cement, chemical additives and pigments provide you with a long-lasting and aesthetic result. Therefore, high-quality materials may increase costs, but ultimately help you achieve better results.

Size of Applications

The size of the project is also an effective parameter on pricing. For patterned concrete applications of large areas, more material and labor will be required. The costs of working in a small area will of course be lower. However, if applications are to be made for large areas, there may generally be price reductions per square meter.

Pattern Selection

Stamped concrete pattern types also have a significant effect on price. More complex and detailed patterns may increase costs, as they require more labor and time. On the other hand, simple patterns may be more affordable. You can achieve affordable and aesthetic results by taking your preferences into account during the project phase.

Labor Fees

The labor costs of companies that provide stamped concrete services, which vary according to quantity and quality, also directly affect the total cost of your project. Since expert teams perform operations that require attention, experience and technical knowledge during application, it is important to prefer qualified workers. This will increase the quality of the service you receive in the long term and will be reflected in your budget.

Considering all these factors, it will be useful to do a detailed research in order to reach clear information about stamped concrete prices. Thanks to the data obtained, you can find the most suitable solutions for your needs and budget. Remember, not compromising on quality while analyzing costs allows you to achieve long-term and aesthetic results.

Stamped Concrete Surface Coating Techniques

Stamped Concrete surface coating techniques are important processes applied to increase the appearance and durability of spaces. These coating methods are of great importance not only in terms of aesthetics; but also in terms of functionality. Together with Decorative Concrete applications, it makes spaces more attractive.

Among these techniques, stamped concrete surface coating applications stand out as the most common. This operation primarily ensures that the floors are long-lasting and resistant to external factors. In addition, it adds a unique atmosphere to the space with different pattern and color options.

1. Color and Pattern Options

It is possible to change the atmosphere of the environment by choosing from among the stamped concrete pattern types. Various alternatives can be created on the floors by using patterned templates rather than plain color applications. These patterns can be designed in many different styles such as natural stone, wood or brick appearances. Therefore, it offers a wide range of options depending on aesthetic concerns and personal preferences.

2. Protective Coatings

After the applied stamped concrete surface coating process, the durability of the surface can be increased with quality protective coatings. These coatings are more resistant to water, chemicals and impacts. In addition, they simplify maintenance processes by facilitating cleaning of the surface.

3. Surface Treatments

Surface coating techniques used in stamped concrete applications generally include pre- and post-casting processes. During casting, correct mixing ratios and appropriate epoxy applications should be performed. Surfaces that need to be smoothed after casting are finished with sanding and polishing processes.

4. Different Application Methods

Since each space has its own needs, stamped concrete application methods also vary. Special coating techniques have been developed for different purposes such as indoor floors, outdoor areas or driveways. Thus, maximum performance is achieved in every area.

Stamped Concrete Surface Coating Techniques increase the aesthetics of spaces while also creating a long-lasting infrastructure. The fact that the practitioners are proficient in these techniques is of great importance in terms of the quality of the results. The fact that venue owners receive professional service by working with the right stamped concrete company will maximize its service life and appearance.

Patterned Concrete Applications

Patterned concrete applications have become one of the most important elements of modern architecture. These applications, which attract attention with their aesthetic appearance and durability, are preferred in the interior and exterior areas of various venues. Such applications increase the visuality by adding to the spaces and also highlight the functionality.

One of the main advantages of these applications is that they offer various pattern options. Stamped concrete pattern types give each space a unique character by being shaped according to the user’s wishes. Patterns that imitate the appearance of natural materials such as stone, brick, wood are frequently used as floor coverings, especially in exterior spaces. At the same time, it offers an ideal option for those who want to create a unique atmosphere in interior spaces.

Application methods are quite diverse. Stamped concrete application methods, when performed by professional experts, directly affect the quality of the application. Usually, after the concrete casting process is completed, patterns are created using special molds. The selection of these molds is very important for the quality of the result. Using the right molds and techniques helps to achieve the desired appearance in the space.

Patterned concrete applications provide advantages not only in terms of aesthetic concerns, but also in terms of durability and maintenance. Such coatings are resistant to external weather conditions and offer a long-lasting solution. In addition, they can be made even more durable with special surface coating processes applied on the applications.

To summarize, patterned concrete applications are an element that enriches spaces with both aesthetic and functional features. Users can beautify their living spaces by evaluating the best application techniques and pattern options according to their needs through the stamped concrete company. In addition to creating different atmospheres with special design requests, it offers a sustainable and long-lasting floor covering solution.

Stamped Concrete Casting Techniques

Stamped Concrete casting techniques play a critical role in terms of the quality and durability of the application. These techniques have been specially developed so that the concrete can have the desired shape and patterns. There are points to be considered during casting, and these points can directly affect the success of the project.

Preparation Before Casting

Stamped Concrete application methods rarely start with the direct casting of the surface. First, the surface needs to be prepared. This stage starts with ground survey. The ground should be arranged in order to provide a solid and smooth surface. Then, mold systems and pattern molds are placed. The most important element to be considered at this stage is that the mold is completely fixed.

Preparation of Concrete Mixture

The components of the concrete mixture are among the elements that determine the casting quality. For a quality patterned concrete application, aggregate, cement, water, additives and color pigments should be mixed in ideal proportions. These elements in the concrete mixture both increase durability and provide an aesthetic appearance.

Casting Stage

The casting process begins with pouring concrete into the prepared molds. At this stage, attention should be paid to the casting speed and technique. Stamped concrete casting techniques are usually supported by vibration to prevent the formation of air bubbles. This ensures that the concrete is distributed equally at every point and creates a smooth appearance on the surface.

Final Processes and Maintenance

Following the casting process, a certain period of time must be waited for the concrete to dry and harden. In general, this period starts from 24 hours and may take longer depending on the weather conditions. It is important to keep the concrete moist during the drying process. This prevents cracks from forming. Finally, the concrete surface must be protected with stamped concrete surface coating techniques. This step ensures that the surface is resistant to external factors and extends its life.

When Stamped Concrete Casting Techniques are applied by experts, they provide superior results in terms of both aesthetics and functionality. Therefore, working with an experienced Stamped Concrete Company in this field is of great importance in order to guarantee success.

Ece Surface Printed Concrete Company and Services

Ece Surface, which specializes in stamped concrete applications, has an important position with its experience in the sector and the quality service it offers. It works to increase the aesthetics and durability of spaces by offering its customers the best solutions in the field of stamped concrete casting techniques and patterned concrete applications.

The company produces decorative concrete solutions with the desired pattern and appearance using modern technologies and innovative application methods. Ece Surface, by prioritizing customer satisfaction, provides all kinds of stamped concrete services needed in different areas, thus standing out from its competitors in the sector. The high-quality materials used in its applications allow long-lasting and aesthetic surfaces to be obtained.

The stamped concrete surface coating services offered by Ece Surface are valuable not only in terms of aesthetics but also in terms of functionality. Thanks to the coating techniques that increase the durability of the surfaces, the space is made resistant to all kinds of weather conditions. In addition, thanks to these services, it becomes possible to clean and maintain concrete surfaces.

The company also adopts a transparent approach to its customers regarding stamped concrete prices. Pricing may vary depending on the size of the projects, materials used and application methods. Ece Surface provides free consultancy to its potential customers, performs the necessary analyses and offers the most suitable price offer. Thus, special solutions suitable for everyone’s needs are produced.

Ece Surface has managed to become one of the reliable addresses in the sector as a stamped concrete company, and contributes to the creation of both aesthetic and durable spaces with the stamped concrete application methods it offers. Whether it is for commercial or individual projects, it is ready to offer customized solutions for all kinds of needs with its professional team. You can take the first step to beautify your spaces by contacting Ece Surface.