Flooring Covering Molds

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Flooring Covering Molds

Flooring molds, also known as floor panel or slab molds, are essential tools in the manufacturing of prefabricated flooring systems. They are widely used in construction, interior design, and industrial applications to produce consistent, durable, and aesthetically appealing floor surfaces. These molds can create a wide variety of textures, patterns, and structural features, ranging from decorative stamped concrete floors to modular interlocking tiles and raised access flooring.

This article explores the types, materials, manufacturing techniques, and applications of flooring molds, as well as the advantages they bring to modern construction and design.

Types of Flooring Molds

Flooring molds vary depending on the flooring material and application. The most common types include:

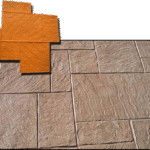

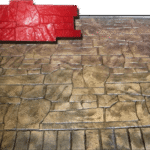

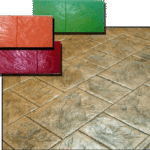

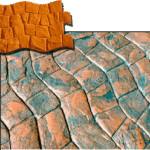

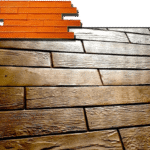

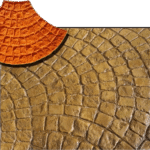

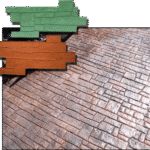

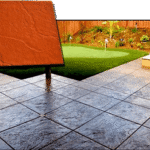

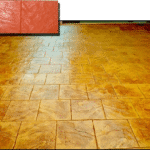

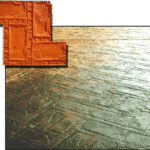

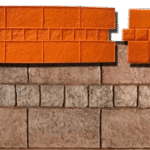

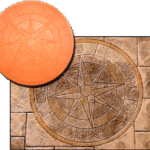

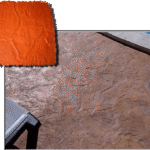

1. Concrete Molds

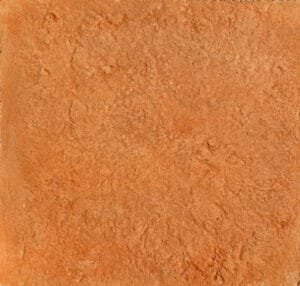

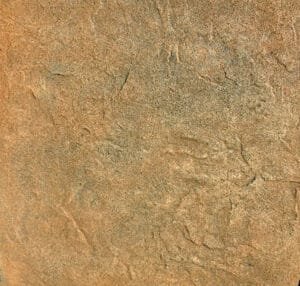

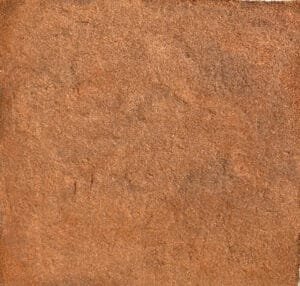

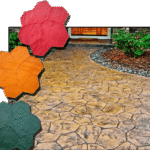

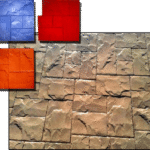

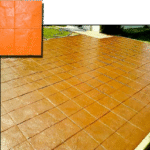

Concrete flooring molds are used to create stamped or textured concrete slabs. These are commonly applied in patios, driveways, walkways, and commercial spaces. The molds come in rubber or polyurethane formats and allow for artistic impressions such as brick, stone, slate, or woodgrain effects.

2. PVC and Plastic Tile Molds

Used to produce floor tiles made of polyvinyl chloride (PVC), polypropylene, or other synthetic materials. These molds are typically injection molded and designed for repeatable use in high-volume tile manufacturing.

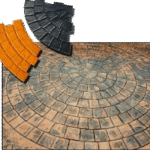

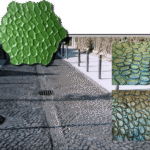

3. Rubber Molds for Interlocking Tiles

Often used for gym flooring, playgrounds, and outdoor walkways, these molds form durable, shock-absorbing tiles. The rubber used is often recycled and poured into heat-resistant, reusable molds.

4. Epoxy and Resin Flooring Molds

Used for producing customized decorative panels or self-leveling flooring kits. Molds for epoxy floors are often silicone-based and help define borders, layers, or embedded elements like glitter, stones, or LED strips.

5. Raised Access Flooring Molds

In commercial environments like data centers or offices, flooring molds are used to create modular panels with metal-reinforced concrete cores. These panels are manufactured with precise tolerances using steel molds in hydraulic pressing systems.

Materials Used in Mold Construction

The material selection for a mold is crucial, as it affects the final quality of the flooring panel, durability of the mold, and production efficiency. Key materials include:

Steel or Aluminum: Used for heavy-duty molds, especially in industrial or high-load environments. These molds can withstand high pressures and are ideal for raised access or concrete slab panels.

Polyurethane and Silicone Rubber: Preferred for decorative concrete stamping and resin-based applications. They are flexible, detailed, and resistant to wear.

Plastic (ABS, Polycarbonate, PP): Lightweight and cost-effective, often used in tile manufacturing and for low-pressure molding applications.

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.Mold Manufacturing Techniques

Depending on the complexity and volume of the production, various methods are used to fabricate flooring molds:

CNC Machining: Ensures precise dimensions and surface finishes, especially for metal molds used in industrial flooring.

Injection Molding: Common for mass production of plastic molds for PVC tiles.

Casting and Vulcanization: Used for rubber molds, which need to maintain both flexibility and shape integrity under thermal stress.

3D Printing: A growing technique for creating custom patterns or limited-series flooring designs. This enables architects and designers to innovate beyond traditional designs.

Applications in Construction and Design

Flooring molds enable a wide range of applications in both indoor and outdoor environments:

Stamped Concrete in Public Spaces: Parks, plazas, and urban walkways benefit from durable, low-maintenance flooring with a stone or wood finish created via stamping molds.

Modular Floor Tiles for Offices and Homes: Easy-to-install, replaceable tiles are produced using high-volume molds, offering quick renovation options and modular flexibility.

Anti-slip Industrial Flooring: Molds are used to create textured surfaces with grip patterns to enhance workplace safety.

Artistic Resin Floors: In luxury homes or showrooms, epoxy molds enable creative installations like river tables or abstract floor art.

Raised Floor Systems: Precision-molded panels with underfloor cable and ventilation routing, critical in IT facilities and commercial buildings.

Advantages of Using Flooring Molds

Flooring molds offer several benefits across industries:

Consistency and Accuracy: Every tile or slab has the same dimensions, ensuring tight installation tolerances.

Speed and Efficiency: Prefabrication using molds significantly speeds up installation and reduces on-site labor.

Customization: Mold-based flooring allows for tailored aesthetics and textures based on client needs.

Cost-Effective Mass Production: Ideal for large-scale projects where uniformity and speed are critical.

Durability: Molded floor components are typically stronger and longer-lasting due to controlled manufacturing conditions.

Challenges and Innovations

While flooring molds offer many advantages, challenges such as wear over time, material limitations, and high tooling costs exist. However, continuous innovations in mold coatings, automation in mold cleaning, and integration with digital design tools (like BIM and CAD) are overcoming these hurdles.

Emerging trends include:

Smart Molds with Sensors: To monitor curing temperature, pressure, or material fill.

AI-based Mold Design Optimization: For reduced material waste and better mold flow.

Eco-friendly Molding Materials: Such as biodegradable or recycled plastic molds.

Conclusion

Flooring molds are indispensable tools in modern construction and interior design. From industrial concrete slabs to bespoke resin designs, these molds serve as the backbone for efficient, aesthetic, and structurally sound flooring systems. As the construction industry continues to embrace prefabrication, sustainability, and digital fabrication, the role of innovative mold technology will only grow stronger.

Whether in urban infrastructure or high-end residential architecture, flooring molds transform raw materials into the durable, stylish surfaces we walk on every day.