Ground Stamped Concrete

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Ground Stamped Concrete

Floor Imprinted Concrete; The concept of housing, which exists in different forms in our world, has changed and effectively taken its current form.

Floor Imprinted Concrete As a result of different applications, tests and processes, the most accurate products and techniques begin to serve us over time. Among these demands, the floor imprinted concrete system, which has recently attracted attention, stands out as a successful product. The advantages of this system, which is truly satisfactory with its features, are also very high. Thanks to these systems that can be applied effectively, you can also get the best results in your buildings.

These floors, which have a magnificent appearance, also appear as solid and healthy systems. They can respond to your expectations very well. The floor imprinted concrete prices, which are quite affordable for those who want to have this process, will bring different results. Thanks to these systems that can be applied to the floor and provide very special results, it will be possible to get the desired result wherever you want quickly and easily. Let’s take a look at the general features of these products that we encounter in the most different ways.

What is Floor Imprinted Concrete?

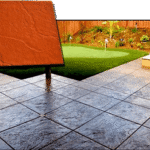

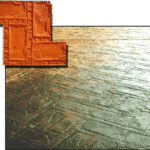

Floor Imprinted Concrete is highly preferred, especially in outdoor areas, as an aesthetic and functional surface coating method. This application aims to imitate the appearance of natural stone, brick or other floor covering materials by adding molds and color pigments to the concrete. In this way, both visual aesthetics are provided and the durability and strength of the concrete are prioritized. Floor imprinted concrete is widely used in parks, gardens, roads and all open areas.

This application process first starts with the floor imprinted concrete cement measurements prepared using special mixtures. Correct mixture ratios have a great effect on the quality and durability of the application. Then, molds specially produced for floor imprinted concrete are used during the application phase to the concrete. During the application, pigments are added to the molds to color them and then the appearance is enriched. When the application is completed, floor imprinted concrete offers both a durable and aesthetic exterior surface.

Many people, seeing the advantages of this application, prefer to replace their existing floors with this material. Floor imprinted concrete not only offers visual aesthetics, but also offers a long-lasting solution by reducing maintenance requirements. These surfaces, which are resistant to water, oil and chemicals, are also frequently preferred, especially in commercial areas.

In summary, the answer to the question of what is ground imprinted concrete can be expressed as a material that offers the aesthetics and durability offered by modern construction solutions. This application draws attention with its reliability and elegance, and can reach a wide audience with affordable prices. Ground imprinted concrete application offers options that will appeal to every taste with various ground imprinted concrete models.

How to Make Floor Imprinted Concrete?

Floor Imprinted Concrete application is a very popular method for creating aesthetic and durable surfaces. However, certain steps must be followed carefully for this process to be carried out successfully. Below you can find the answer to the question of how to make floor imprinted concrete.

First, it is very important to prepare a suitable ground. The ground must have a flat surface and be cleared of all debris. If the ground is not smooth, it must be properly leveled and compacted. At this stage, it can be supported with gravel or sand if necessary.

After the preparation stage is completed, the floor imprinted concrete cement dimensions must be determined. At this stage, mixing the materials in the right proportions plays a critical role. It is generally recommended to mix cement with sand and aggregates in certain proportions. The consistency of the mixture should be suitable for the process; it should be neither too watery nor too solid.

Afterwards, the mixed concrete should be poured onto the ground and spread evenly. After the concrete is poured, a trowel can be used to smooth the surface properly. This process helps the surface look more aesthetic.

Another important step is the use of special printing molds during the application of floor stamped concrete. These molds are placed on the poured concrete to create the desired pattern. The molds are usually removed within 24-48 hours depending on the hardening of the concrete. Thus, the pattern is clearly visible.

After the hardening period of the concrete, it is recommended to cover it with a surface protector as a final step. This provides both a decorative and aesthetic appearance and contributes to the longevity of the surface.

The steps to be followed and the details to be considered during the production of Floor Stamped Concrete greatly affect the quality of the application. When each stage is applied meticulously, there is no doubt that an aesthetic and durable floor will emerge. If you do not want to do this process yourself, you can consider getting professional service.

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.Floor Stamped Concrete Models

Floor Stamped Concrete types create a wide range of floor covering systems that offer different aesthetics and functionality. There are different floor stamped concrete models suitable for every space and need. These models can be preferred in both indoor and outdoor applications. Here, let’s take a look at the most popular floor stamped concrete models.

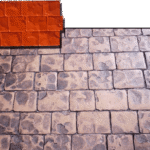

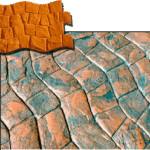

Natural Stone Look Models

Floor stamped concrete models that resemble natural stones are ideal for those looking for elegance and grace. This design adds a rustic atmosphere to your space while also providing advantages in terms of durability. It is frequently preferred especially on garden paths or outdoor seating areas.

Brick Look Models

Floor stamped concrete options with brick patterns allow you to create a classic and warm atmosphere. Especially in structures or gardens with historical textures, such models can be preferred to give the space a nostalgic atmosphere. In addition, this design is also very easy to clean and maintain.

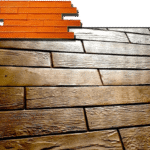

Wood Look Models

Floor stamped concrete designs with a wood look combine the warmth of nature with a modern touch. When used in interior and exterior spaces, such as borders or balconies, it offers a very stylish look. Wood look floor stamped concretes eliminate the disadvantages of traditional wooden floors and offer a long-lasting alternative.

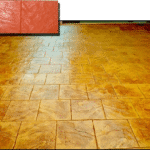

Geometric Patterned Models

For those who love modern designs, geometric patterned floor printed concrete models are a great option. These types of floor coverings attract attention with their unique patterns and are especially preferred in commercial areas such as shopping malls and restaurants. These patterns, created by combining different colors, add a dynamic atmosphere to the space.

Colored Concrete Models

Colored floor printed concrete applications provide an eye-catching appearance even under sunlight at noon. Thanks to the color pigments added to it, the space is added to liveliness. It is especially used in children’s playgrounds and sports areas. In addition, colored models can be customized according to the personal tastes of the users.

These various floor printed concrete models offer many advantages in terms of both aesthetics and durability. Users can easily find and apply the floor printed concrete options suitable for their own spaces. Choosing the most suitable design, along with the points to be considered during the application phase, will increase both the visual perception and the comfort of use of the space.

Floor Imprinted Concrete Prices

Floor Imprinted Concrete prices vary depending on the scope of the application, the size of the project, and the quality of the selected material. Therefore, it is very important to pay attention to various factors before evaluating the prices.

First of all, there can be a large price difference between the types of floor imprinted concrete used. For example, there is a cost difference between a standard floor imprinted concrete and well-known models that include special effects and require more workmanship. Therefore, you need to decide what kind of aesthetics and durability you want. Choosing between the floor imprinted concrete models you are considering will affect your budget.

In addition, the size of the application area is also an important factor affecting the prices. If your project covers a large area, the total cost will naturally increase. However, since bulk purchase discounts can usually be applied in large projects, it may be useful to take this into consideration. In this way, your floor imprinted concrete purchase process can become more economical.

The ground of the place where the application will be made can also affect the costs. If the existing ground is not smooth and solid, additional workmanship and material may be required. In this case, making a detailed evaluation about how ground imprinted concrete is made and the preliminary preparations to be applied will clarify both the process and the financial situation.

Finally, in order to get accurate information about ground imprinted concrete prices, it is very important to contact various companies operating in the market and get price quotes. By comparing the options offered by different companies, you can create a roadmap where you can get the best quality service at the most affordable cost.

In summary, a detailed research on pricing will allow you to get a floor that is both aesthetic and functional. Avoid making a decision without learning more about ground imprinted concrete application; in this way, you will be able to make a more conscious investment.

Ground Imprinted Concrete Application Examples

Ground Imprinted Concrete applications are becoming increasingly popular due to the combination of aesthetics and durability. These applications appear in different forms in various areas. Ground imprinted concrete examples, especially those used in different places such as public areas, commercial spaces and private properties, show how wide the range of the application is.

For example, among the examples of ground imprinted concrete applications, park and garden arrangements attract a lot of attention. Bouquet flower beds, walking paths and resting areas are given an aesthetic form using this technique. The patterns preferred in such applications ensure integration with nature, while user safety is also prioritized with the non-slip feature of the floors.

In addition, the use of ground imprinted concrete is also seen intensively in commercial areas. In places such as shopping mall parking lots, cafe terraces and restaurant gardens, floors designed with various pattern and color alternatives change the general atmosphere of the space and at the same time attract the attention of customers. Thanks to ground imprinted concrete models, businesses can create their own unique style.

The use of ground imprinted concrete is also quite common in industrial areas. While durability and longevity are at the forefront in factory floors and warehouse areas, the aesthetic value provided by this floor is also undeniable. Such applications ensure that the floors are both functional and visually satisfying.

The examples of stamped concrete applications attract attention in all areas with their variety and aesthetic structure. These applications, ranging from garden arrangements to commercial spaces, industrial areas to private properties, are enriched with the ground imprinted concrete cement measurements and special application techniques used. If you also want to benefit from these applications, you can get information from local experts by doing a detailed study and implement your own project suggestions.

Ground Imprinted Concrete Cement Measurements

Ground Imprinted Concrete applications offer many advantages in terms of aesthetics and durability. However, in order to achieve these advantages, the materials used must be in the right dimensions. At this point, ground imprinted concrete cement measurements come into play and are an important element that determines the quality of the application.

Why Are Cement Measurements Important?

Correct cement measurements ensure the durability and longevity of the application, while also minimizing the problems that may be encountered during application. Incorrect measurements can cause the surface to crack, become slippery or wear out rapidly. Therefore, determining the ideal ratios of cement and other materials for the production of ground imprinted concrete is a critical step.

General Measurement Ratios

The most commonly used cement measurements in ground imprinted concrete applications are generally as follows:

Cement: Generally 1 unit

Sand: 2 units

Coarse Aggregate: 3 units

Water: 50-70% of the cement weight

Although these measurements provide a basic ratio, they may vary depending on the requirements of the project and environmental conditions. In particular, factors such as the area of use, climatic conditions and the load to which the surface will be exposed may require adjustment of these ratios.

Application Tips

Quality of Materials: The quality of materials such as cement, sand and aggregate will determine the result to be obtained at the end of the application.

Mixture Preparation: When mixing the materials, the irrigation rate should be carefully adjusted. Using too much water can reduce durability, while using too little water can affect the smoothness of the application.

Drying Time: Keeping the concrete moist for a certain period of time after application increases its durability.

By determining the correct floor stamped concrete cement measurements, it is possible to obtain high-quality and long-lasting surfaces. Detailed planning and material selection before application are critical to the success of the project. It should not be forgotten that the needs of each project are different and therefore the measurements may need to be adapted according to the characteristics of the project.

Floor Stamped Concrete Purchase Guide

Purchasing Floor Stamped Concrete is an important stage in construction projects. Choosing the right products affects the success of the projects in terms of both aesthetics and durability. In this article, let’s discuss in detail the elements you should pay attention to when purchasing Floor Stamped Concrete.

First of all, it will be useful to know the answer to the question of what is Floor Imprinted Concrete. This is an application technique that allows creating surfaces in various patterns and colors. However, choosing the right materials increases the effectiveness of the application process. At this point, using quality materials is the basis for creating a long-lasting and aesthetic floor.

Floor Imprinted Concrete prices may vary between regions. In general, prices vary depending on the quality of the material used, the size of the project and the application area. Therefore, it is important to compare prices with local suppliers when planning your budget. When doing your research, you should pay attention not only to prices, but also to product quality and the reliability of the supplier.

In addition, you can examine the various models offered by suppliers to find the most suitable material for floor imprinted concrete application. These models include pattern, color and surface texture options. These details should be carefully selected for the aesthetic harmony of your project.

In addition, the floor imprinted concrete cement dimensions required for the application are also important. The type of cement to be used plays a big role in terms of durability. You can get information from your supplier about the most suitable type of cement for your project.

When purchasing your floor stamped concrete, you should do as much detailed research as possible and consider the price-performance balance. In addition, you can get inspired by examining various floor stamped concrete application examples and determine the unique appearance of your project in advance. Remember, good planning and the right material selection are the keys to a successful floor project.