Grouting

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Grouting

POLIFER 206 / 209 /420 / 830 / 635

Polypropylene wire for concrete reinforcement

Description: Polifer is a polymer-added polypropylene wire reinforcement that provides high elasticity, bending strength, impact resistance and reinforcement function in concrete.

Areas of Use

In ground concretes,

Shotcrete – sprayed concrete,

In concrete exposed to acids,

In pumped concrete,

In mortars,

In tunnels,

Especially in outdoor concretes exposed to reinforcement corrosion.

Features

Stainless.

High alkali resistance.

Provides higher density in concrete.

Increases the impact and tensile strength of concrete.

High resistance to dynamic loads and fatigue.

High bending strength.

Resistance to shrinkage.

Prevents crack formation and spreading.

Has water repellent properties.

Resistant to chemicals and microorganisms.

Provides perfect mixing in concrete.

Does not wear like steel wires in shotcrete machines.

Minimizes wire loss in shotcrete.

Consumption: 5 – 10 kg / m³

Wire Types and Dimensions According to Purpose of Use

POLIFER 206 (6mm)

Mortar and thin coatings

POLIFER 209 (9mm)

Mortar, thin coatings

POLIFER 420 (20 mm length x 0.18 – 0.22 mm width)

Shotcrete

Mortar and thin coatings.

Precast

POLIFER 635 (35 mm length x 0.20 – 0.25 mm width)

Industrial floors. (6-8cm)

Shotcrete.

Precast

POLIFER 830 (30 mm length x 0.80 – 1.00 mm width)

Industrial floors.

Mixing of Wires into Concrete

Polypropylene wires are added to dry or wet concrete in a truck mixer or concrete plant. Packages should be added at 30-second intervals. After the last package is added, the mixer should be mixed at high speed for 5 minutes.

Concrete Design

In order to get good results from wire-reinforced concrete, the following characteristics of the mixture should be taken into consideration.

Correct granulometry,

Correct cement dosage,

Correct water/cement ratio,

Concrete curing,

Adding polypropylene wire to concrete reduces the workability of the concrete. Workability loss is greater in high dosage and long wires.

In order to prevent workability loss and to make the wire-reinforced concrete mixture easy to use, superplasticizer concrete additives should be used instead of more water. Concrete slump should be at least 12 cm.

Technical Data

Specific gravity: 0.95 gr / cm³

Strength: 450 -750 N / mm²

Elasticity: 3.8 kN / mm²

Flexibility: %10

Melting point: 180 C°

Water retention: %0.01

Color: Gray

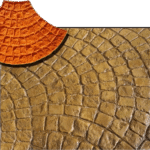

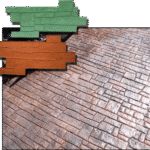

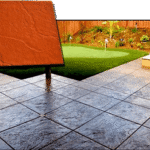

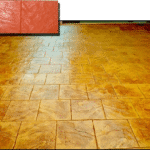

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.Packaging: In 2 and 5 kg packages depending on the type of steel wire.

What are Concrete Reinforcements?

Concrete reinforcements are important elements that increase the durability and functionality of concrete structures. Concrete is not very resistant to tensile force on its own. For this reason, concrete reinforcements are used as a structural element that combines the tensile strength of steel with the compressive strength of concrete. These reinforcements, usually made of steel, are available in different thicknesses and diameters and play a critical role in various construction projects.

Concrete reinforcements basically fulfill two main functions. The first is to increase the resistance of the structure against forces such as tension, bending and shear. The second is to minimize cracks and deformations that may occur over time by preserving the structural integrity of the concrete. In this way, the constructed structures become more durable and long-lasting.

Concrete reinforcement models vary depending on the requirements of the construction and the project. There are various preference options designed for different types of structures. In addition, each model has certain advantages and disadvantages; this allows civil engineers to choose the most suitable model according to the needs of the project.

Concrete reinforcement prices vary depending on the quality, type and size of the material used. These reinforcements, which are offered in different price ranges in the markets, vary according to the quality of the material to be selected and the need. Therefore, it is important to conduct detailed research before projects.

Concrete Reinforcements occupy a critical place in the construction sector and are among the indispensable building blocks of modern structures thanks to the advantages they provide. Application processes and quality are factors that directly affect the performance of the structure. Therefore, they should be selected and applied by experts in the field.

How are Concrete Reinforcements Made?

Concrete Reinforcements are one of the basic components of the construction sector and it is of great importance to make them correctly. They are generally used to increase the strength of concrete and ensure its structural integrity. So, how are Concrete Reinforcements Made? Here are the main steps to consider in this process:

First, the necessary materials for Concrete Reinforcements need to be selected. At this stage, the quality and type to be used should be determined according to the needs of the structure. When choosing quality concrete reinforcements, it is important to evaluate between different types of concrete reinforcement and concrete reinforcement models. In material selection, the quality of the steel in the reinforcement, its dimensions and coating features should be carefully examined.

Secondary, another important question for the question of how are Concrete Reinforcements Made