İndustrial Floor

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

İndustrial Floor

Industrial Floor, Specializing in the selection and application of the right floor covering systems for your needs, Ece Baskı Beton will offer you the most appropriate surface solutions with its years of experience and product support from the companies it cooperates with, considering the different needs of the users.

The floor coverings that Ece Baskı Beton applies are functional, resistant to harmful effects and abrasion from environmental conditions. They are extremely hygienic and do not harbor bacteria. They are easy and fast to apply. Their areas of use are extremely wide. They can be used in a wide variety of places, from industrial areas where conditions are harsh to laboratory floors where chemical effects are present, from gyms to health centers that require absolute hygiene, and from office and store floors where aesthetics are at the forefront.

What is Industrial Floor?

Industrial floors are flooring systems that are frequently encountered in the field of industry and trade, and prioritize durability and functionality. Such floors are generally used in high-traffic areas such as factories, workshops, warehouses and stores. These floors, equipped with various industrial floor covering materials according to the area of use, are designed to meet many criteria such as durability, aesthetics, safety and hygiene.

One of the basic features of these floors is that they can last for a long time without deformation under heavy loads. In addition, when answering the question of what is an industrial floor, it should be noted that these floors are resistant to chemicals, temperature changes and other harmful effects. This durability is extremely important, especially in the chemical industry, food production facilities and engineering fields.

Industrial floors offer a great advantage in terms of work safety, as they generally have a smooth and non-slip surface. In addition, these floors are also very easy to maintain and clean. Floor surfaces can be brought to a hygienic state by using industrial floor cleaning methods. Thus, a healthy working environment is provided by preventing the formation of bad odors and harmful bacteria.

On the other hand, the flooring materials to be selected during industrial floor applications are very important. The materials generally used include epoxy, polyurethane, concrete and more. These materials offer variety in terms of both aesthetics and functionality. Different industrial floor models vary according to the needs of users.

The concept of Industrial Flooring covers standardized and high-performance flooring solutions in the industry. These floors are widely used in different sectors by increasing safety in workplaces and offering a long-lasting and aesthetic appearance.

How is Industrial Flooring Made?

Industrial flooring is a type of flooring known for its durability and functionality. These floors are generally preferred in factories, businesses with warehouses and industrial areas. Industrial floor applications are carried out effectively with the right material selection and application techniques. So, how is industrial flooring made?

The first step is to determine the basic requirements of the project. Factors such as the purpose for which the floor project will be used, the loads it will be exposed to, heat and chemicals should be taken into consideration. At this stage, appropriate industrial floor covering materials should be selected. The most suitable one for the need should be preferred among various materials such as concrete, epoxy, polyurethane.

In the second stage, the existing ground should be prepared properly. If there are problems such as breaking, cracking or subsidence, the ground should be leveled in a healthy way. If there is a problem such as groundwater, appropriate drainage systems should be established to prevent these situations. Industrial floor concrete application is a key step in creating a proper foundation.

In the third stage, the selected industrial floor covering materials should be made ready to be poured or laid in the application area. If epoxy coating is preferred, the material mixture should be prepared in appropriate proportions and meticulously. After the material is applied, it will need to be cured for a certain period of time. This period varies depending on the type of ground and the temperature in the environment.

In the final stage, the smoothness and flatness of the surface to be applied should be checked. The floor quality is ensured with the final checks made after the application. When all these steps are completed, the resulting industrial floor solutions will be durable for many years and will meet the needs of the workplaces.

Another important point to remember is industrial floor maintenance. Regular maintenance and cleaning after the application is completed will extend the life of the floors. In this way, you can get the best return on your investment in the long term.

Industrial Floor Covering Materials

It is extremely important to be careful in the selection of materials to be used in the industrial floor covering process. These materials not only provide an aesthetic appearance, but also fulfill important functions such as durability, easy maintenance and safety. In this context, here is detailed information about some of the prominent industrial floor covering materials.

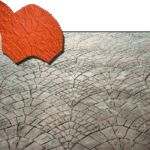

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.Epoxy Coating

Epoxy is a durable coating material widely used in industrial facilities. Such coatings are known for their chemical resistance and resistance to impacts. Epoxy coatings can be customized with various color options and surface patterns, thus increasing the aesthetics of the spaces. In addition, epoxy coating applications are usually fast and can be completed without disrupting the construction process.

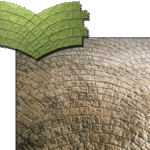

Polymer Coating

Polymer-based coatings generally attract attention with their flexibility and abrasion resistance. These materials are ideal especially for heavy construction equipment and areas exposed to heavy traffic. Polymer coatings are not affected by water and create a safe floor with their anti-slip properties.

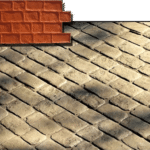

Concrete Coating

Industrial floor concrete is also a common choice and stands out with its durability and longevity. Concrete coatings can be used for many years with proper maintenance and protection. Concrete coatings, which offer a flat and smooth surface, can also be given an aesthetic appearance with various surface treatments.

PVC Coating

PVC coatings are especially preferred in sanitary installation areas and food production facilities. It has an important place among industrial floor solutions with its easy cleaning, hygienic structure and color options. PVC coatings provide a safe floor thanks to its non-slip properties.

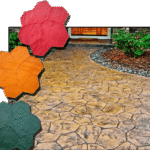

Tile Coating

Finally, tile coating options also attract attention. These coatings can be produced in different patterns and colors. Tile coatings, which offer a modular structure, can be easily repaired and replaced when necessary. It is an ideal choice especially for businesses that want to make a difference in certain areas.

There are many options among Industrial Floor Coating Materials. Each material offers advantages according to different needs and areas of use. Choosing the right material will ensure that the floors are long-lasting, durable and have an aesthetic appearance. For this reason, the special needs of the area should be taken into consideration before the floor coating process.

Industrial Floor Models

Industrial floor applications offer different solutions according to the various needs of workplaces. At this point, when choosing between industrial floor models, it is important to consider the characteristics and requirements of the area you will use. Each model has its own advantages and application areas.

First of all, one of the most widely preferred industrial floor coating types is epoxy floor coatings. This coating stands out with its chemical resistance and is frequently used especially in factories, warehouses and workshops. Epoxy coating provides high impact resistance and provides a long-lasting floor in environments where heavy machinery and vehicles are located.

Another popular option is polyurethane floor coatings. These coatings allow light movement in spaces thanks to their flexible structure and prevent floors from collapsing. In addition, polyurethane coatings are notable for their waterproof properties. For this reason, they are frequently preferred in facilities in the food sector.

Concrete floors are a common choice, especially in large areas. While industrial floor concrete is known for its durability and strength, it can be enriched with various coating materials to be applied to the surface. The ease of maintenance of this floor model is a great advantage for business owners.

In addition, industrial floor models also include coatings that are resistant to abrasion in stressful environments. For example, non-slip surfaces are specially designed coatings created to prevent work accidents and are especially important in metalworking and assembly areas.

Finally, when making a choice regarding industrial floor applications, it is necessary to consider the cleaning and maintenance of the floors. Choosing the right model is of great importance not only in terms of aesthetics, but also in terms of work safety and ease of maintenance. Therefore, determining the appropriate model according to the needs of the businesses will also reduce your costs in the long run.

In this context, it may be useful to get expert consultancy when creating industrial floor solutions. Remember that each floor type provides its own benefits in different applications and needs.

Industrial Floor Prices

Industrial floor applications are widely used in many sectors and therefore industrial floor prices also vary widely. There are many factors that affect prices and therefore it is important to understand the elements you need to consider when planning your project budget.

First of all, the type of industrial floor covering plays a big role. Different coating materials can vary in terms of price. For example, special products such as epoxy coatings usually have higher costs, while simpler concrete floors or vinyl coatings can offer more economical options. Therefore, when choosing between industrial floor covering materials, you should consider your intended use and budget.

Another important factor is the size of the area where the application will be made. Depending on the question of how to make industrial floors in larger areas, labor costs and material needs increase. In addition, the preparation process (time and labor) required in floor applications is another factor affecting prices.

You also need to consider floor maintenance and repair costs. Coatings made using quality materials can be less costly in the long term in terms of industrial floor maintenance and cleaning. For a long-lasting application, initial investments can provide advantages in the future. In addition, industrial floor cleaning methods can also create certain costs.

Industrial Floor Prices vary depending on many factors. When planning your project budget, you should take into account many elements from material selection to application size. In addition, by working with a professional team, you can achieve both quality and cost-effective solutions.

Industrial Floor Maintenance Tips

Industrial floors are of great importance for increasing the efficiency of the workforce and supporting various industrial activities. However, regular maintenance is necessary to extend the life of industrial floors and maintain their performance. Here are a few important maintenance tips to consider in this context:

Regular Cleaning

Industrial floor cleaning methods are one of the basic elements of maintenance. Residues such as dirt, rust and oil accumulated on the floor can cause wear on the surface of the floor over time. Therefore, it is recommended to clean regularly using appropriate cleaning materials. In particular, deep cleaning can be achieved by using special industrial floor cleaning machines.

Chemicals to Avoid

Care should be taken when choosing cleaning products used in floor maintenance. Acidic or corrosive chemicals can damage industrial floor covering materials. Instead, cleaners with a suitable pH balance and suitable for the floor structure should be preferred.

Surface Assessment

During industrial floor maintenance, it is also important to regularly assess the floor surface. When cracks, collapses or other signs of damage are observed on the floor, these problems must be repaired urgently. Timely interventions will prevent bigger problems.

Water Treatment

Water ingress to the floor surface causes both slipperiness and can cause damage in the long term. Therefore, drainage systems should be checked regularly to prevent the formation of water puddles. In addition, appropriate equipment should be used to dry the floor surface.

Choosing the Appropriate Floor Covering

Maintenance operations can be made more effective with the right choices among industrial floor models. For example, durable and non-slip coating materials should be preferred in heavy-duty areas. The features of floor covering materials should be evaluated well.

If these tips are followed, industrial floors provide both advantages in terms of work safety and are long-lasting. It should not be forgotten that regular maintenance and cleaning reduce costs by increasing the performance of the floors.

Industrial Floor Cleaning Methods

Since industrial floors are used in areas exposed to high-density workload, cleaning and maintenance are very important. Industrial floor cleaning methods play a major role in ensuring the longevity of the floors and work safety. Applying the right methods both provides an aesthetically pleasing appearance and increases the functionality of the floors.

First of all, it is essential to establish a regular cleaning routine for industrial floor maintenance. The weekly or monthly cleaning frequency may vary depending on the intensive use of the floors. The tools and materials used during cleaning are also of great importance. For example, high-quality cleaning machines suitable for hard surfaces should be used.

In addition to these, there are also chemical cleaners and natural solutions in industrial floor cleaning methods. While chemical products can dissolve stains and dirt faster, natural solutions are more environmentally friendly and safer for user health. Silicone-based cleaners and water-based solutions are especially preferred in places where food production is carried out.

Another important point is the types of floor coverings used during industrial floor applications. For example, epoxy coatings are very effective in reducing direct contact of chemical substances with the floor. Using products suitable for these coatings while cleaning will extend the life of the floors.

In addition, another thing to consider when cleaning hard floors such as industrial floor concrete is to avoid abrasive materials. Instead of abrasive sponges or brushes, soft-textured cleaning cloths should be preferred. Water use should also be carefully adjusted during cleaning; excessive water can increase the risk of slipping on the floors.

Finally, one of the most effective maintenance tips applied among industrial floor cleaning methods is to regularly dust the floors. Minimizing dust and dirt with vacuum cleaners or large-sized industrial vacuum cleaners greatly facilitates general cleaning.

Regular cleaning and proper maintenance not only provide a stylish floor, but also prevent accidents that may occur in terms of work safety. Therefore, having information about the cleaning and maintenance of industrial floors is extremely important for businesses.