Stamped Concrete Polish LSS

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Stamped Concrete Polish LSS

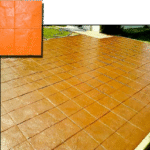

Stamped concrete polish LSS is used to cure the concrete after all fresh concrete and concrete surface hardener applications and to prevent dusting by obtaining an insulated layer in the concrete.

With stamped concrete protective polish, the performance of the concrete surface is increased and dusting is prevented by applying it on old concrete when desired. At the same time, a shiny appearance is obtained on the surface. LSS is a transparent liquid based on solvent-based acrylic resin.

When applied, it creates an insulating layer in the concrete and prevents rapid evaporation of water in the concrete. The applied material also provides insulation by creating a transparent and protective film layer, and increases the durability of the concrete by preventing dusting of the surface.

What is Stamped Concrete Polish?

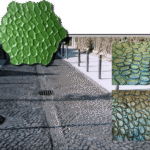

Stamped concrete polish is a very popular surface coating technique today. It has become an important choice for space owners who are especially looking for an aesthetic appearance and durability. This technique ensures that concrete surfaces are more beautiful, solid and long-lasting with a special process applied to the concrete.

Concrete Polishing Techniques

Concrete polishing techniques form an important part of stamped concrete polish. Thanks to these techniques, concrete surfaces are made smoother and gain less dirt retention. Polishing application makes the concrete more resistant to external factors and also provides an aesthetic appearance.

Why Should Stamped Concrete Polish Be Preferred?

Durability: The applied polish prevents the surface from cracking and peeling.

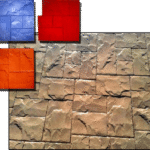

Aesthetic Appearance: An original space design is achieved with different pattern and color options.

Easy Cleaning: Polished surfaces offer a more practical choice in terms of cleaning.

Economic: It provides a cost advantage in the long term thanks to its long life.

Stamped Concrete Polish is an application that offers many advantages both aesthetically and functionally. When done correctly, your concrete surfaces become not only reliable but also visually impressive. Therefore, when looking for an answer to the question of what is stamped concrete polish, it is important to consider the benefits offered by this process.

How is Stamped Concrete Polish Made?

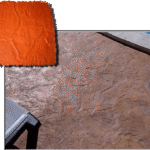

Stamped concrete polish application is an important process that provides an aesthetic appearance while also increasing durability. This process supports the protection and long-term health of concrete surfaces. Here are the steps to follow for concrete polish application:

1. Surface Preparation

Cleaning: The first step is to thoroughly clean the concrete surface. This means removing dust, oil and other dirt. Appropriate cleaners can be used to remove stains and rust on the surface.

Repair: If there are cracks or damage on the surface, stamped concrete repair should be done. In this process, the cracks should be filled and a smooth surface should be obtained.

2. Preparation Before Application

Material Selection: The concrete polish suitable for your needs should be selected. A model that allows you to achieve the desired appearance should be preferred among transparent concrete polish or other options.

Tools: It is important to provide the equipment required for the application. Generally, tools such as rollers, brushes and spray guns are used.

3. Application of Concrete Polish

First Coat Application: The selected polish should be applied to the surface as specified. Take care to reach every point of the surface with long and smooth movements. After waiting for the first layer to dry for sufficient time, the second layer should be applied.

Second Layer Application: After the first layer has dried, the second layer is applied with the same technique. This stage increases the density of the polish and creates a smoother surface.

4. Maintenance and Protection

Drying Time: Make sure that a certain amount of time has passed for the applied polish to dry completely. This period may vary depending on environmental conditions.

Maintenance: It is important to maintain the surface after application. For stamped concrete surface maintenance, dust and dirt should be cleaned regularly, and the polish should be renewed if necessary.

These steps answer the question of how stamped concrete polish is applied. Attention should be paid to each stage to obtain high-quality results and ensure a long-lasting surface. Remember, correct preparation and application will provide the desired aesthetics and durability.

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.Concrete Polishing Techniques

Concrete polishing techniques are processes applied to increase the aesthetic appearance of concrete surfaces and strengthen their durability. These methods can be used both indoors and outdoors, allowing concrete surfaces to gain a smoother and brighter appearance. Here is a detailed description of these techniques:

1. Mechanical Polishing

Tools: This method is done using special polishing machines and sanding discs. The machine gradually sands the top layer of the concrete surface.

Application: Usually, the process starts with sanding discs of different grades and continues with increasingly thin discs. In this way, the roughness on the surface is gradually reduced and the desired shine is achieved.

2. Chemical Polishing

Materials: Chemical polishing consists of special chemical mixtures applied to the surface. These materials, b