Surface Hardeners

Ece Surfacing - Stamped Concrete - Stamped Concrete Molds - Stamped Concrete ApplicationsEce Surface - Stamped Concrete - Construction Chemicals

Surface Hardeners

Reinforced concrete surface hardener

DURAPLATE is a high strength concrete surface hardener developed for industrial floors resistant to heavy loads, containing micro reinforcement, resistant to abrasion, impact and dust, applied on freshly polished concrete.

DURAPLATE PFR contains micro polypropylene wire with organic additives, DURAPLATE SFR contains micro steel wire.

Areas of Use

In structures such as factories, warehouses, repair shops, parking lots, garages, fairgrounds, supermarkets, aircraft hangars

Pavements, roads, parking lots, outdoor areas.

In automotive, textile factories.

In electrical, chemical, printing sector floors.

In industrial floors exposed to heavy loads.

Features

The strength of the concrete surface increases 8-10 times compared to normal concrete.

The absorbent feature of the concrete surface decreases.

It reduces dust on the concrete surface and is easy to clean.

High strengths are formed on the concrete surface thanks to the low water / cement ratio.

Resistance to industrial chemicals such as engine oil, mineral oils, light acids, detergents increases.

The applied hardener becomes a part of the concrete structure.

It can be used indoors and outdoors.

It resists the flaking that occurs as a result of freezing and thawing in concrete.

Thanks to the wire reinforcement it contains, high resistance is provided to the concrete surface against impact and abrasion.

PFR micro wire reinforcement has a non-rusting structure.

Consumption

3 – 8 kg / m² according to load and traffic density

3 – 5 kg / m² for light and medium loads

5 – 8 kg / m² for heavy loads

The material makes a 2 – 4 mm thick coating on the concrete surface.

Packaging and Storage

25 kg. moisture-resistant kraft bag; Shelf life is at least 6 months in a dry and protected warehouse.

Technical Data

Compressive strength: 80 – 85 N/mm², 28 days

Elasticity modulus: 28,000 N/mm², 28 days

Abrasion resistance (Bohme): 1.2 cm³ / 50 cm²

Impact resistance (2000 cycles): 20-25% weight loss

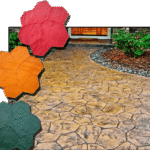

Color: Gray, red, green, black

What are Surface Hardener Products?

Surface hardener products are important materials frequently used in building inspection and floor coverings. These products have been developed specifically to increase the durability of concrete surfaces and to increase their resistance to abrasion and chemicals. The variety of concrete surface hardener products extends to a wide range with specific formulations for different application areas and needs.

First of all, acrylic, epoxy and polyurethane-based hardeners stand out among the hardener product types. Acrylic-based hardeners stand out with their fast-drying properties. They are generally preferred in outdoor applications. Epoxy hardeners, on the other hand, offer more durability and resistance to chemicals, so they are widely used in industrial floors. Polyurethane-based products stand out with their flexibility and are an ideal option in heavily loaded areas.

Another important surface hardening method is liquid hardeners. These products are applied directly to the concrete surface, filling the porosity inside the surface and increasing durability. Areas of use include parking lots, factories and warehouse floors.

In addition, the properties of hardening materials are also an important criterion. Products that stand out with features such as long-lasting, environmentally friendly and fast-drying are among the factors that affect users’ preferences. Surface hardener applications offer both economical and practical solutions thanks to the advantages these materials bring to the structure.

Surface Hardener Products play an indispensable role in modern construction and industrial applications. Choosing quality and suitable products ensures that the floors are long-lasting and reliable. Many brands and varieties available on the market offer different solution alternatives to users, creating a wide range in terms of surface hardener prices and brands.

Concrete Surface Hardener Usage Areas

Concrete surface hardener products are widely used in many sectors. The advantages and protection provided by these products have become an important requirement especially in industrial applications, commercial areas and special projects. Here are some examples of concrete surface hardener usage areas:

Our website provides general information on the stamped concrete solutions you need for your property, construction site, villa, park, or garden. Our team will be happy to provide you with customized solutions based on your detailed requests.1. Industrial Areas

Industrial facilities are places where heavy machinery and equipment are used. For this reason, the durability of the floors is of great importance. Surface hardener products play a critical role in increasing the resistance of concrete floors used in factories, storage areas and workshops against abrasion and impacts. In this way, it provides a long-lasting floor by reducing unwanted repair costs.

2. Commercial Areas

In shopping malls, public markets and other commercial areas, the aesthetic appearance and durability of the floor directly affect the customer experience. Concrete surface hardeners create floors that are resistant to heavy traffic by providing both elegance and durability in such areas. In addition, these products offer easy cleaning and maintenance.

3. Automotive Services

Vehicle maintenance services and garages are in constant interaction with chemicals, oils and heavy vehicles. Hardening materials help the floors in these areas to be non-slip, while also providing long-term protection by providing chemical resistance.

4. Sports Areas

Gyms and outdoor sports areas require durable floors. Floors obtained by using the surface hardening method become more resistant to abrasions in sports waves. In addition, the aesthetic properties of the floors are increased, providing a pleasant environment while doing sports.

5. Residential Projects

Finally, the use of concrete surface hardener products is also common in residential projects. Especially in garages, terraces and garden paths, these products provide both visual aesthetics and increase the durability of the floors.

Concrete Surface Hardener applications have spread over a wide range. The advantages they provide in every sector show how important these products are. The variety of areas of use brings up the question of how to use surface hardener, and with the right application, it becomes possible to benefit from all these advantages.

Surface Hardening Methods and Advantages

Surface hardening methods have an important place in the construction and floor covering fields and play a critical role in increasing the durability of surfaces. These methods offer significant advantages in terms of increasing the resistance of surfaces to abrasion, providing water-repellent properties and generally extending their life.

Surface Hardening Methods

There are many concrete surface hardening technologies. This method is generally divided into two main groups: chemical and physical hardening.

In chemical hardening, specially formulated hardening materials are used. These products penetrate the concrete after application and provide hardening within the concrete structure. The most commonly used chemical methods include silica, fluoride and polymer-based products.

Physical hardening, on the other hand, is generally carried out with mechanical processes. Such hardening methods include high pressure and heat applications. In particular, as a result of surface smoothing processes on the concrete, surface hardness is increased.

Advantages

Surface hardening methods have many advantages. First of all, thanks to the surface hardener product varieties, existing surfaces become more durable. In this way, the wear and tear rate is significantly reduced, especially on industrial floors. In addition, the surfaces obtained with these methods become waterproof. Water can cause cracks and gaps on concrete surfaces over time. The hardening process helps prevent these negative effects.

Another advantage is that a synergy is created between the surface hardener and surface protection methods. It protects the surfaces from the harmful effects of external factors by protecting them. This reduces maintenance costs and preserves the aesthetic appearance of the surfaces.

When the Surface Hardening Method is used, both economic and functional benefits are provided. When appropriate choices are made for concrete structures, it is possible to obtain long-lasting and durable surfaces.

Properties of Hardening Materials

Hardening materials are important components used to increase the durability of concrete surfaces and provide wear resistance. The properties of these materials affect the physical and chemical structure of the concrete and contribute to obtaining a long-lasting surface. Therefore, the selection of the right surface hardener products is one of the determining factors of the application results and the performance of the surface.

First of all, the most striking feature of the hardener materials is their durability. In surface hardening applications, the materials used are generally expected to have high compressive strength. In this way, a long-lasting surface can be obtained even in areas carrying heavy loads or in outdoor applications. In addition, the waterproofing properties of concrete surface hardener products also provide an important advantage. Such hardeners prevent water accumulation and leakage on the surface, preventing the concrete from deteriorating over time.

Another feature is their chemical resistance. Hardener materials must be resistant to acidic and alkaline effects. Thus, concrete surfaces used in industrial areas are less damaged when they come into contact with chemicals. In addition, the slip resistance of the materials used with surface hardening methods is also very important. This situation helps prevent accidents by providing a safe working environment, especially in floor areas.

Hardener product types include those in powder and liquid form. Powdered products are usually applied by sprinkling on the surface, while liquid hardeners are applied directly to the surface. Both forms have their own advantages, but careful planning and technique are required during application. In order to answer the question of how to use surface hardener, it is important to consider the homogeneous distribution of these products during application and the drying times that must be taken into account.

Finally, the prices and brands of hardening materials should be carefully selected by the consumer. There are many different product varieties offered by different brands on the market, and the quality of these products is directly related to the differences in price range. When the right choice is made, it both offers an economical solution and provides long-term protection.

All these features are among the critical elements for durable and long-lasting surfaces aimed to be obtained with surface hardener applications.

Surface Hardener Application Techniques

Surface hardener application techniques are of vital importance for the effective use of surface hardener products. The correct application of these techniques not only increases the durability of the surfaces, but also ensures their longevity. The main application methods and details to be considered when using concrete surface hardener are listed below.

1. Surface Preparation

The first step is to properly prepare the area where the surface hardener will be applied. The surface must be clean and free of dust, dirt or oil before application. This stage is critical to ensure that the hardener materials make full contact with the surface.

2. Product Selection and Quantity Determination

Among the hardener product types, the one that is suitable for the application area and needs must be selected. In addition, correctly calculating the amount of product planned to be used is important for the efficiency of the application. In general, an appropriate amount must be determined according to the size of the usage area.

3. Application Methods

The most commonly used methods among the application techniques are as follows:

Sprinkle Method: The hardener product is applied by sprinkling on the surface. It is generally preferred on small and medium-sized surfaces. With this method, the hardener is well distributed on the surface.

Plaster Method: In this method, the surface hardener mixture is applied to the surface with a spatula or similar tool. It is preferred to create a thicker layer and is generally suitable for more difficult surfaces.

Spray Method: It is used in cases where the surface is large. The hardener material is distributed homogeneously on the surface with special spray machines. This method provides a fast application opportunity and at the same time allows the material to penetrate the surface well.

4. Curing Time and Follow-up

After the application is completed, a certain curing time is required for the surface hardener application areas. This period allows the hardener to effectively penetrate the surface. In general, this period varies depending on the type of application and weather conditions, so the manufacturer’s instructions should be followed.

These surface hardener application techniques make surfaces more durable with correct application. The best answer to the question of how to use surface hardener is to perform these application techniques effectively and carefully. In this way, long-lasting and durable surfaces can be obtained by ensuring a strong integration with surface protection methods.

Surface Hardener Prices and Market Trends

Today, surface hardener products are frequently preferred in the construction and floor covering sector. The prices of these products vary depending on many factors. First of all, the variety of concrete surface hardener types is one of the biggest reasons for these price differences. The quality, brand and contents of hardener materials directly affect the cost.

Surface Hardener Product Types

Surface hardener product types can generally be grouped according to their chemical formulations. While there are price differences between organic and inorganic hardeners, the advantages offered by these products should also be taken into account. In general, organic hardeners may be more affordable, while inorganic options that offer high durability are slightly more expensive. Considering market trends, an increase in the prices of these products is observed due to the intense demand of users.

Market Trends and Supply-Demand Balance

In recent years, surface hardener prices have also changed with the growth in the construction sector. Increasing construction material costs and labor costs are reflected in hardener product prices. At the same time, the demand for environmentally friendly and durable products affects the development of the sector in this area. Brands develop and offer new formulations in line with user demands. This creates indirect effects on surface hardener prices and brands.

Pricing Strategies

Different companies apply different pricing strategies when launching surface hardener products. These strategies include discounted campaigns, price advantages provided in bulk purchases, and advantages obtained with long-term contracts. Users being aware of these strategies can help them obtain products that suit their needs at more affordable prices.

Surface Hardener Prices and market trends are constantly evolving with the growth and changes in the sector. Making the right choices and conducting market research will provide significant benefits in terms of both cost and quality. When surface hardener and surface protection methods are also taken into consideration, it is possible to increase the return on investment.

Use of Hardener Compatible with Surface Protection Methods

With the increasing use of surface hardener products, the integration of these products with surface protection methods is also gaining great importance. Surface hardener applications extend the life of concrete or other floor types, while also providing significant benefits in terms of durability and aesthetics.

The most common and effective surface protection methods include water repellent, chemical resistance enhancing and rain protective coatings. Surface hardener products, when combined with these methods, further increase the durability of concrete surfaces. Studies have shown that the combination of these two approaches makes floors more resistant to abrasion, cracking and other environmental effects.

Regular use of hardener materials reduces the risk of stains and contamination on surfaces. For example, an applied concrete surface hardener reduces the absorption of water on the floor, which minimizes water-related problems. In addition, such products contribute to the creation of a safe work surface in industrial areas by providing protection against chemical substances.

There are important points to consider regarding how surface hardening methods and hardener products can be used in surface protection projects. In each application, the targeted protection level must first be determined, and then the appropriate hardener products must be selected. At this stage, making the right choices among hardener product types is the key to providing long-lasting and effective protection.

Finally, the answer to the question of how to use surface hardener is the key to success in surface protection work. Following the application techniques correctly will ensure that the protective properties are maximized. For example, ensuring appropriate temperature and humidity conditions increases the effectiveness of hardening products. All these factors are important for achieving the highest level of success in protecting surfaces.